How Beauty Machines Enhance Skin Texture and Tone for a More Even Complexion

Beauty machines have become a revolutionary force in the skincare industry, offering innovative solutions that effectively enhance skin texture and tone, ultimately leading to a more even and radiant complexion. These devices utilize advanced technologies such as microcurrents, radiofrequency, LED light therapy, ultrasound, and laser treatments to target multiple layers of the skin with precision and minimal invasiveness. By stimulating the skin’s natural processes, beauty machines promote cell regeneration, collagen production, and improved circulation, all of which play crucial roles in refining skin texture and evening out skin tone. One of the key ways beauty machines enhance skin texture is through their ability to boost collagen and elastin synthesis. Collagen is a vital protein responsible for maintaining the skin’s firmness and smoothness, but as we age, collagen production naturally declines, leading to roughness, fine lines, and uneven texture. Beauty machines, particularly those using radiofrequency and ultrasound, deliver controlled heat deep into the dermis, stimulating fibroblast activity that encourages new collagen growth. This renewed collagen helps to plump and smooth the skin, reducing the appearance of wrinkles, pores, and uneven surfaces.

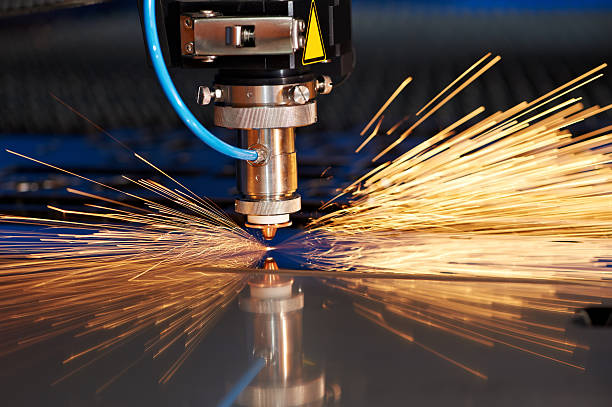

Over time, users notice a softer, more refined texture that feels smoother to the touch. In addition to improving texture, many beauty machines are designed to even out skin tone by targeting pigmentation issues such as dark spots, redness, and hyperpigmentation. LED light therapy devices are especially popular for this purpose, as different wavelengths of light penetrate the skin to reduce inflammation and inhibit the production of excess melanin, the pigment responsible for discoloration. Blue light can help combat acne-causing bacteria, while red and near-infrared lights promote healing and reduce redness, balancing the overall complexion. Laser-based machines also work by breaking down pigmented cells, encouraging the skin to shed these damaged layers and reveal fresher, more uniform skin beneath. Another important benefit of beauty machines lies in their ability to enhance blood circulation and lymphatic drainage. Improved circulation brings more oxygen and nutrients to skin cells, vital for maintaining healthy skin and repairing damage. At the same time, enhanced lymphatic drainage helps eliminate toxins and reduce puffiness, contributing to a clearer and more luminous complexion.

Many devices use gentle massage techniques or microcurrent stimulation to encourage this circulation, resulting in skin that appears revitalized and glowing. What makes beauty machines especially appealing is their non-invasive nature and the convenience of integrating them into regular skincare routines. Unlike harsh chemical peels or surgical procedures, these technologies typically involve minimal downtime and can be adjusted to suit various skin types and sensitivities. This accessibility allows individuals to maintain consistent treatments that gradually improve skin texture and tone without discomfort or significant risk. Konmison beauty machines offer a multifaceted approach to enhancing skin texture and tone by stimulating collagen production, reducing pigmentation irregularities, and boosting circulation. Through these combined effects, they help users achieve a smoother, more even complexion marked by youthful radiance and health. As technology continues to evolve, these devices are becoming increasingly sophisticated, making it easier than ever to enjoy professional-level skincare benefits from the comfort of home or in specialized clinics. This advancement not only improves appearance but also promotes overall skin health, empowering people to look and feel their best.